FEATURED KEY TECHNOLOGY

MUSCLE PE

The ultimate braid. Long casts, durable and free flowing.

MUSLE PE is the result of combining a trio of key Daiwa line technologies, UVF (Ultra Volume Fibre), Si2+ / Si3+ Silicone & TOUGH PE fibre. MUSCLE PE is a high-density PE that is resistant to rubbing, improves durability, reduces noise, and increases flight distance. It has the characteristic of being trouble-free for anglers, giving you confidence when on the water.

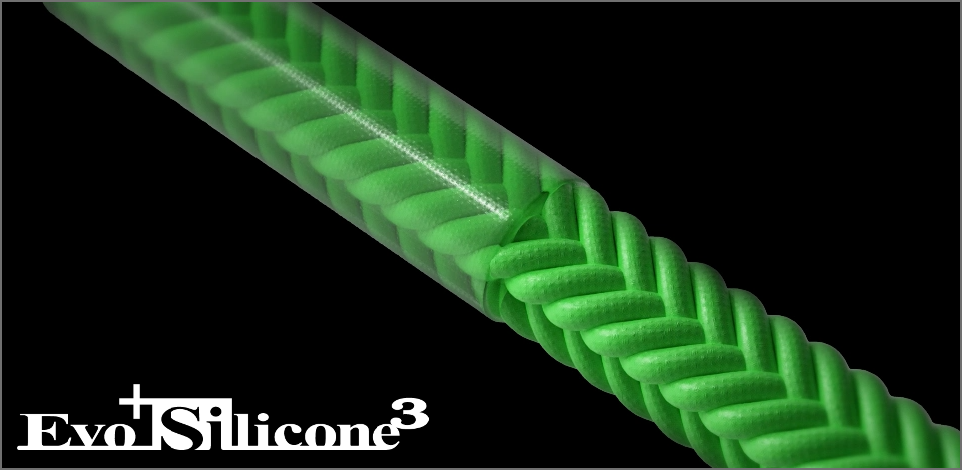

EVOSILICONE Si2 / Si3

Slick silicone coating. Increases durability and performance.

Daiwa’s unique special silicon processing “+Si” and “+Si2” have been further powered up!! EvoSilicone Si3+ increases wear resistance and durability by approximately 1.3 times of “Si2+”. It is smoother and more scratch resistant creating a line that is more durable and has better handling providing trouble free line management.

IZANAS

Dense round profile raw material. Increased abrasion resistance.

A high performance, line-construction material. Line made using IZANAS is stronger, more abrasion resistant, and more consistent in profile and performance. The raw material profile is rounder than conventional raw PE materials and once weaved creates a line with the same thickness throughout and therefore has a constant breaking strain for the whole length of the spool.

COATING PE

Hydrophobic coating. Repels water and grit form entering line.

COATING PE silicon coating helps braid to not absorb any water, importantly this means the braid also does not absorb the silt & sediment present in that water which is the #1 cause of braided line wear over time. By shedding the water thanks to its hydrophobic properties, lines using COATING PE will last longer than traditional braided lines, providing more value & greater performance.

MORE TECHNOLOGY

TOUGH PE

Round profile. High strength & durability.

TOUGH PE is a new material that is thicker and rounder than conventional yarns, achieving increased strength, abrasion resistance, and durability. We twist these raw threads together to create 4, 8, and 12 strand braids that offer greater strength than conventional PE materials.

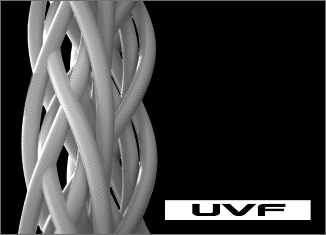

UVF

Ultra Volume Fibre. Unique weaving process.

UVF (Ultra Volume Fibre) is DAIWA’s unique processing method that condenses the fibres while braiding them, and is characterised by high wear resistance and strength. The process is used in many of Daiwa’s high quality braids and in MUSCLE PE construction.

X4 | X8 | X12

4 ,8 & 12 Strand braids

Daiwa creates 4, 8 &12 strand braids to accomodate all angling scenarios. While the diameters (example PE2) are the same when comparing 4, 8 & 12 strand braids they each have varied characteristics. As the strand count goes up the density, smoothness and roundness will increase.

X’LINK TECHNOLOGY

Fluoro Leader. Ultimate abrasion resistance.

The X-Link process is a game-changer for the fishing line industry. The X-Link method alters the molecular structure of the fluorocarbon line itself, bonding individual particles on a chemical level. This change in the chemical composition results in a line which is much stronger for its given diameter.