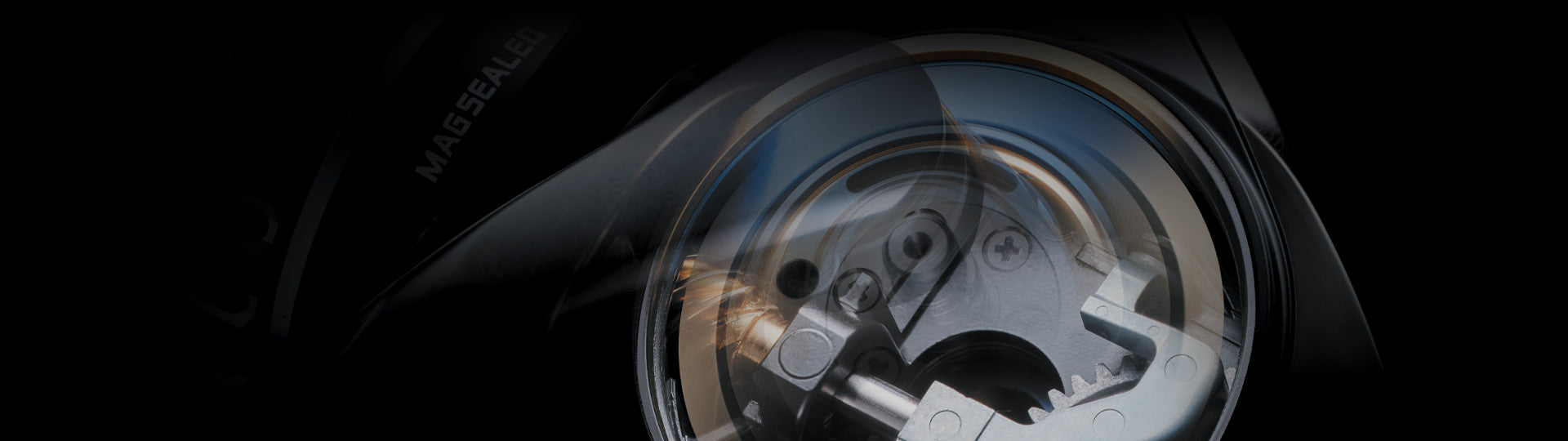

The next generation of large spinning reels have been designed in pursuit of powerful reliability, enabling anglers to target the largest fish around the world.

POWERDRIVE DESIGN consists of two technology units: the body unit “POWERDRIVE ENGINE” and the rotor unit “POWERDRIVE ROTOR”, a spherical rotor shape that achieves both high rigidity and low inertia.

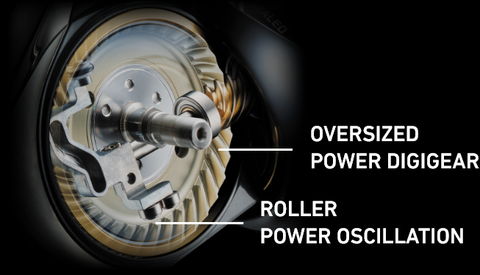

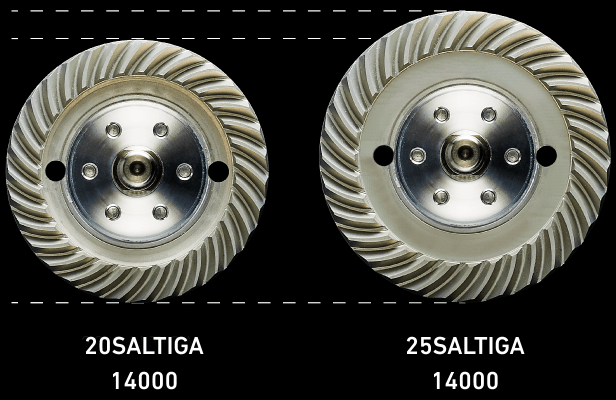

Oversized Power Digigear

The highly durable G1 Duralumin Tough Digigear has been made 10% larger and 6% thicker, making it the strongest gear ever. Even during long, hard fights, the gears are designed to maintain a stable meshing, minimising deflection. By significantly reducing the power transmission loss, exceptionally smooth winding is achieved.

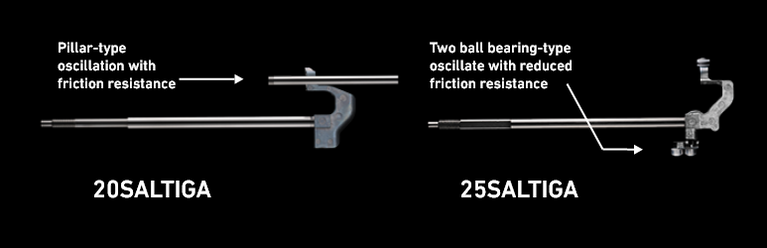

Roller Power Oscillation

When fighting large fish where high loads are constantly being applied, the frictional resistance of the oscillation mechanism caused by reeling leads to a loss of power transmission. In order to reduce this friction as much as possible, the sliding pillar has been upgraded from the conventional pillar to a two ball bearing type oscillator. This has improved the oscillation efficiency by approximately 30% from 20 SALTIGA, providing a smooth initial response even under high loads, and light, powerful reeling.

The oscillator mechanism has been changed from the conventional type to a two ball bearing type oscillator.

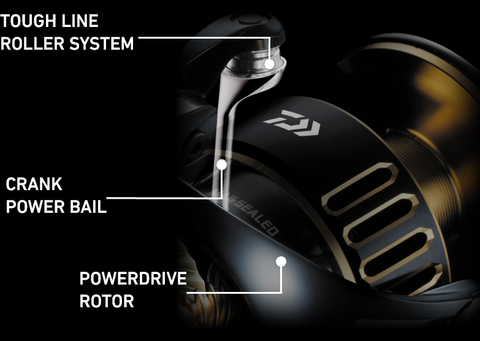

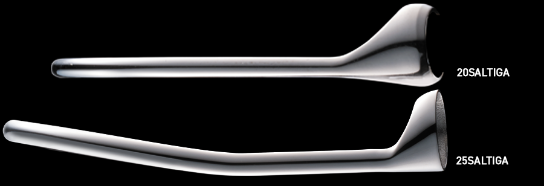

Crank Power Bail

In tough fights, the most important thing is to instantly reel in the line no matter when or where you are. The bail shape with an optimally inclined crank and a strengthened spring mechanism ensure that the tensioned line is guided to the line roller and prevent unexpected opening and closing. In addition, the hollow pipe structure with a thick shaft also ensures high rigidity.

The new crank shape ensures that the tensioned line is guided to the line roller. At the same time, the opening and closing angle of the bail has been revised and the spring mechanism has been strengthened to prevent accidental opening and closing. The line feed performance to the line roller has been greatly improved, especially in jigging scenarios.

Tough Line Roller System

In order to withstand repeated high loads, the roller shaft is designed with a larger support surface and is integrated with the bail arm, eliminating the rattling that previously occurred at the joint and significantly improves durability. In addition, the newly designed PE-only line roller reduces friction with the line, achieving lighter winding. This tough new mechanism significantly improves rigidity, durability and trouble-free performance.

The roller shaft support surface has been designed to be larger and withstand repeated high loads. In addition, the direction of the screws have been changed in order to integrate the roller shaft and the bail arm. There are no joints in the most heavily loaded area, increasing rigidity. The newly designed line roller that has been specialised for PE lines, has reduced line sliding resistance by approximately 3%.